-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

Aluminum Angle Profiles: Key Considerations for Choosing the Right Material for Your Project

2024-12-30

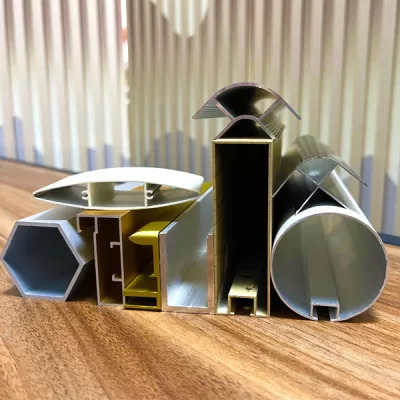

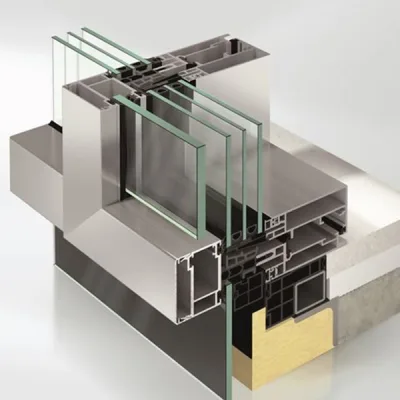

Aluminum angle profiles are versatile and widely used components in various construction, engineering, and manufacturing applications. These sections are characterized by their specific right-angle geometry, whereby they provide structural supports, reinforcement, and frames.

Selecting the appropriate aluminum angle profile can be one of the most crucial choices for the success of your project, whether you are creating a structural support system or developing a custom metal frame. The following important factors will assist you in choosing the ideal material for your requirements.

1. Material Grade and Alloy

First and foremost, the most crucial element to take into account when choosing aluminum angle profiles is the quality of the material or alloy. A variety of qualities pertaining to strength, resistance to corrosion, and weight are determined by the composition of aluminum alloys.

Aluminum 6061, one of the most widely used materials for structural purposes, has a high strength-to-weight ratio and good resistance to corrosion. It can be anodized and welded, and it is quite adaptable. Although it is normally less robust than 6061, aluminum 6063 is utilized for architectural or decorative purposes because it has a superior surface quality and is easier to mold.

2. Strength and Durability

The strength of the aluminum angle profile is considered a critical issue, especially in load-bearing applications since the material needs to support considerable weight or endure mechanical stresses. While the inherent nature of aluminum is lighter compared with steel material, it also can possess substantial strength depending on the alloy and temper.

Because of this, aluminum is a highly good substitute for heavier metals like steel, particularly in sectors like construction, automotive, and aircraft that require low weight.

3. Corrosion Resistance

Because of the protective oxide layer that forms, aluminum has a natural resistance to corrosion, which is one of its most significant benefits. However, the alloy and finish can affect the corrosion resistance level.

Anodizing, for example, deepens the oxide layer, increasing the aluminum’s resistance to corrosion and providing a beautiful, long-lasting finish. Aluminum angles can also significantly improve appearance and corrosion resistance by painting or powder coating them. Selecting the appropriate corrosion-resistant treatment is crucial to extending the service life of your aluminum angle profiles under challenging environmental circumstances.

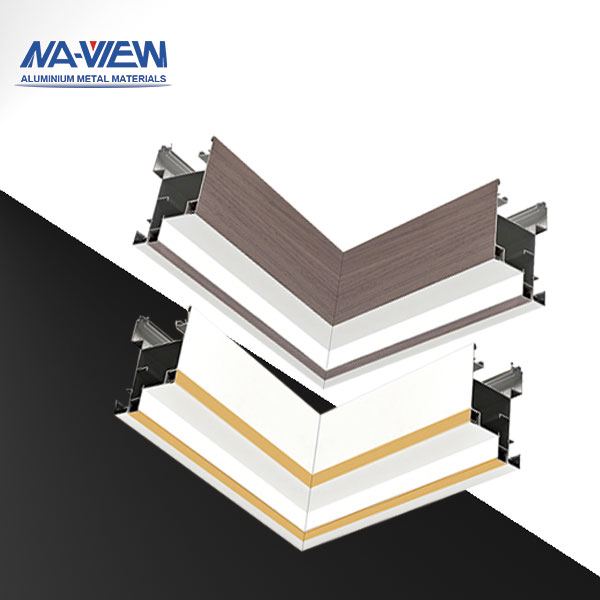

4. Size and Dimensions

There are several sizes of aluminum angle profiles available. The profile’s size will affect its weight, strength, and handiness. It’s critical to choose a size that is neither too big nor too delicate while still meeting the load and stress requirements of your project.

Certain circumstances, such as special usage or confined spaces, may call for custom sizes and cuts. Naview is one of several manufacturers that offer customizable options to meet these demands.

5. Machinability and Fabrication

Aluminum angles can be cut, welded, and manufactured far more easily than other metals like steel. Nonetheless, the specific alloy and temper may affect the material’s ease of machining.

For example, 6061 aluminum’s high degree of machinability makes it perfect for customized fabrication and welding. In the event that your project calls for extra machining or modifications to the aluminum angle profiles, workability is a crucial factor.

6. Cost Considerations

Lastly, there is cost to consider. Generally speaking, the total cost of the aluminum angle profiles will go up with stronger alloys and more specialist finishes like anodizing. Selecting the appropriate material for a project requires striking the perfect balance between cost and performance/durability.

Conclusion

It requires consideration of a number of factors to choose the appropriate aluminum angle profile for a project. These include material grade, strength, corrosion resistance, size, and cost, among other considerations. Understanding these key factors can help you choose the best aluminum angle profile to meet your project needs and ensure its long-term success.