-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

Comparing Aluminum H Profiles with Other Structural Shapes

2024-11-26

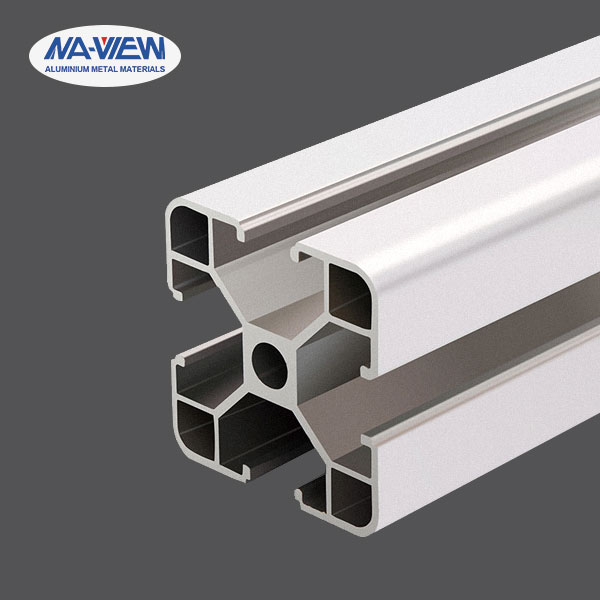

Aluminum H profiles are crucial components in contemporary engineering and manufacturing processes because of their shape and the useful qualities that aluminum naturally possesses. An H-shaped cross-section gives them structural stability and aluminum’s natural corrosion resistance and lightweight strength make these profiles a versatile option.

Compare the advantages of aluminum H profiles with other common structural shapes, such as I-beams, T-profiles, and square tubes. Each shape has unique properties that make them ideal applications for specific uses. Understanding these differences helps manufacturers choose the best solution for their needs.

Key Features of Aluminum H Profiles

Aluminum H profiles have a balanced strength with good load distribution. The H-shaped profile has two flanges parallel to each other and joined together by a central web, which gives it good resistance against bending and torsion.

Therefore, H profiles are suitable for load-carrying constructions, frameworks, and applications that demand stability when surfaces are under stress. The thickness of these profiles remains uniform for consistent performance while allowing for easy machining, welding and cutting operations.

Aluminum as a material adds appeal to H profiles. It boasts an excellent strength-to-weight ratio, making it most valuable in industries such as construction and transportation, which desire to reduce weight but not compromise strength. Besides this, the natural resistance of aluminum to corrosion makes the H profiles befitting for both outdoor and marine applications. The durability and aesthetic finish can also be greatly improved by anodizing or coating.

Comparison with I-Beams

I-beams, also known as H-beams in some regions, have a similar design to aluminum H profiles but differ in flange and web proportions. Typically, I-beams are narrower in their flanges and thicker in their web, therefore concentrating their strength along the vertical axis. This makes them remarkably fit for applications such as supporting vertical loads in bridge construction and building frameworks.

In contrast, the load in aluminum H profiles is distributed more evenly between the vertical and horizontal axes, making it more versatile. The H profile works out more versatile for multidirectional forces, which explains why it can be used for trusses, scaffoldings, and modular frameworks. While I-beams work great for the most heavy-duty scenarios of load-carrying, aluminum H profiles are preferred in constructions where the task involves lightweight and flexibility with structural reliability.

Comparison with T Profiles

The T profiles take their name from the T-shaped cross-section they bear, with a single flange continuing perpendicularly from the web. T profiles are often used as connectors or reinforcements in construction and assembly applications. While the T profile is excellent in joining components in the case of lateral loads, they cannot replace H profiles in applications where multidirectional stresses are involved, since they do not possess a twin-flanged structure.

Aluminum H profiles are stronger when used as independent structural elements due to their double flange configuration, which increases stability and strength. Also, the H shape allows more surface area for joining or attaching components, which is advantageous in complex assemblies.

Comparison with Square Tubes

Square tubes, featuring a hollow, square-shaped cross-section, are another widely used structural shape. Their closed design provides excellent torsional resistance and uniform strength in all directions. Square tubes are commonly used in applications like fencing, framing, and mechanical supports, where torsional stability and a clean, uniform appearance are priorities.

While square tubes are strong and easy to work with, they are not as effective as H-beams in distributing loads around a set axis. The open nature of the H profile structure offers better access and interfacing in modular design compared to square tubes. This makes them ideal in frameworks that need easy assembly and dismantling. Many aluminum H profiles are lighter compared to equivalent strength square tubes, thus enabling advantages in weight-sensitive applications.

Conclusion

Compared to other structural shapes, aluminum H profiles provide an excellent balance of strength, adaptability, and lightweight design. While I-beams, T profiles, and square tubes all have their respective advantages, aluminum H-sections meet most industrial needs.