-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

Comparing Aluminum Profile Sections to Other Materials in Manufacturing

2024-12-13

Among the various materials that are available in the manufacturing industry, aluminum profile sections have grown in popularity for various industries. When compared to other common materials like steel, wood, and plastics, their unique qualities make them highly versatile and reliable. This passage explores the advantages and limitations of aluminum profile sections relative to these materials, focusing on factors like strength, weight, cost, and durability.

Strength-to-Weight Ratio

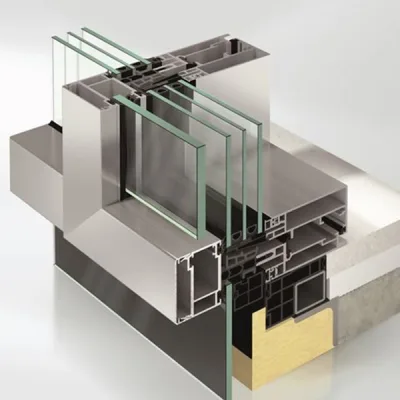

The remarkable strength-to-weight ratio of aluminum profile sections is one of their most notable qualities. Aluminum is perfect for applications that need structural stability without adding a lot of weight because it is strong and lightweight. This is especially beneficial in sectors like construction, automotive, and aerospace, where weight reduction can result in increased productivity and lower energy usage.

Aluminum is about one-third as dense as steel, making it much lighter than steel while yet being robust enough for the majority of uses. Aluminum is the preferred material in applications where mobility and weight reductions are crucial, despite steel’s significantly higher tensile strength. Because they lack aluminum’s structural integrity, materials like wood and plastic have restricted use in heavy-load applications.

Corrosion Resistance

The inherent ability of aluminum profile sections to withstand corrosion is another significant benefit. Aluminum forms a protective oxide layer on its surface when it comes into contact with air, which helps to stop corrosion and gradual deterioration. Because of this characteristic, the material is especially well-suited for outdoor and marine applications where it will be exposed to moisture and other environmental factors.

Steel, on the other hand, rusts easily and requires additional coatings or upkeep to last unless it is treated or alloyed (like stainless steel). The environment can also degrade the structure of wood by causing it to decay, bend, or get infested with insects. Plastic will not corrode but may deteriorate under long exposure to UV radiation or extreme temperature fluctuations, while aluminum is resistant under such circumstances.

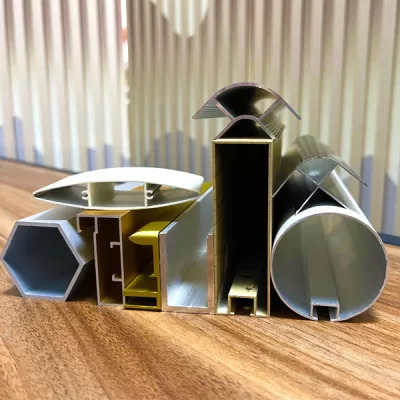

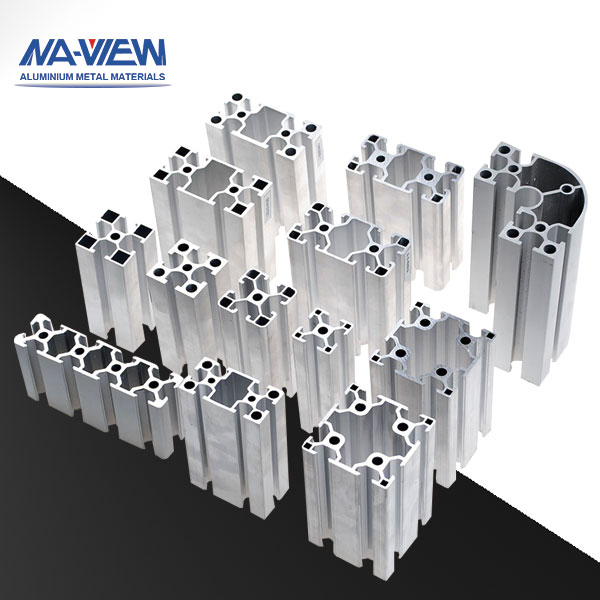

Customizability and Design Flexibility

Aluminum offers unmatched design versatility because of its malleability, which makes it simple to extrude into intricate shapes and profiles. Aluminum profile sections can be tailored by manufacturers like Naview to meet particular needs, making it a flexible option for both common and specialist applications. The anodizing, painting, or coating of aluminum can further enhance its appearance or improve functional aspects such as thermal conductivity or insulation.

Steel may also be produced in almost any shape, but this is generally a more costly and energy-intensive process. Although wood and plastic offer some design freedom, their mechanical drawbacks make them unsuitable for applications requiring strength under demanding circumstances.

Cost Considerations

Although using aluminum profile sections has several benefits, the cost is frequently a deciding factor when choosing materials. In general, aluminum costs more per unit weight than plastic, steel, or wood. But in the long term, its longevity, low maintenance, and durability make it cost-effective.

When very high strength is required or when the budget is tight, steel might be the better option. And because wood and plastic are generally inexpensive, they are frequently utilized in less demanding situations where performance and durability are less important.

Conclusion

Aluminum profile sections are distinguished from other materials by their unique blend of durability, strength, and weight. They stand out as one of the greatest choices for the majority of industries because of their qualities including recyclability, design flexibility, and corrosion resistance.

Although other materials like steel, wood, and plastic each have advantages of their own, aluminum’s versatility guarantees its continued dominance in modern manufacturing.