-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

Why Curved Aluminum Profiles Are the Future of Design and Construction

2025-04-25

In the realm of modern construction, there feels to be a growing demand for innovation. Architects and engineers continue to push the limits in what they can design, and a new material is becoming a powerful solution: curved aluminum profiles. As aluminum has long been known for its strength, it for lightweight and corrosion resistance, curved aluminum profiles are going to be a defining characteristic of buildings and infrastructure in the future. But why are these curved aluminum profiles going to change the future of design and construction?

Ultimate Design Flexibility

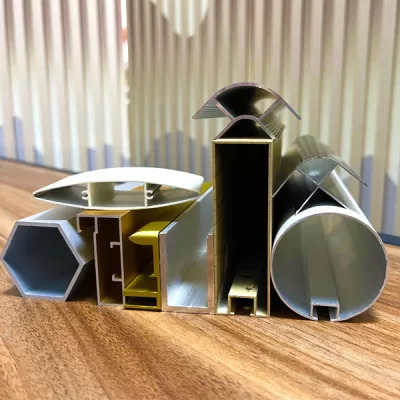

Architects currently seek options that deviate from typical straight lines and boxy structures. Curved aluminum provides their clients with organic, flowing designs that may have been difficult, impractical or expensive to achieve in the past. It is true that these curved profiles may be used to create all types of designs, from sleek contemporary building facades to more curvaceous forms found inside the buildings as furniture/accent pieces. The ability to form curved shapes with aluminum means designers have more options to choose from. This additional flexibility has the ability to make buildings more modern or create new architectural designs altogether.

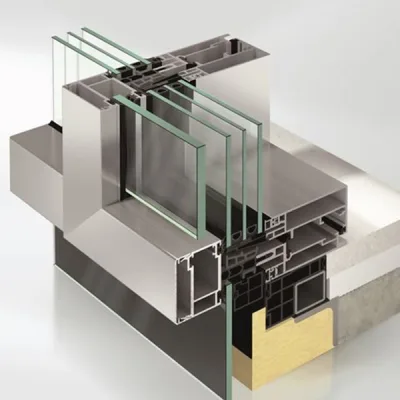

Superior Strength-to-Weight Ratio

Aluminum is lightweight but very strong, and can be used effectively in modern construction. The curves will increase the design’s complexity, but will not limit a portion of material’s load-bearing capability. This makes aluminum profiles amenable to structural applications and decorative purposes while intrinsic offers very desirable forms with little weight. This may be especially advantageous for high-rise structures and bridges, to reduce overall weight from a structural standpoint.

Distinctive Aesthetic Appeal in Design

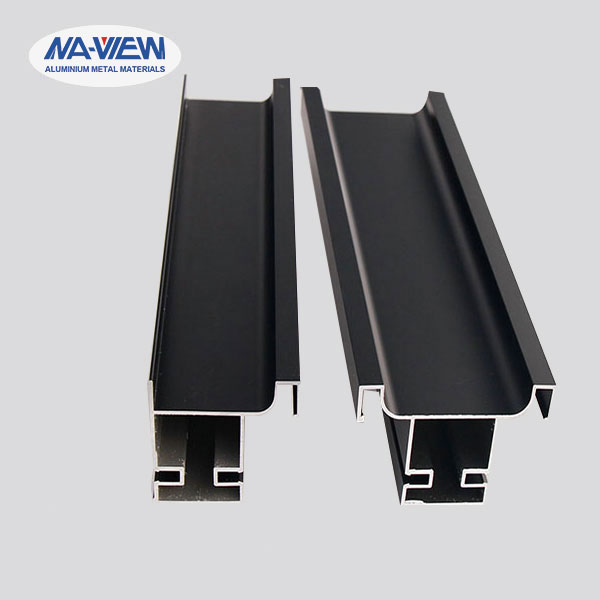

Curved shapes can add fluidity and elegance in any structure, be it a high-tech office building or a public space. With aluminum, which can be anodized or painted in countless colours and finishes, the designer has more control over the visual impact of a building project. These profiles can be implemented in more than just exterior façades, but in interior detail as well making an effective visual statement and improving the overall feel.

Exceptional Durability

As it has natural corrosion resistance and is suitable for use in all environments – interior and exterior, highly humid and coastal areas. As a construction materials, curved aluminum has longevity and you can trust that your building or structure will maintain its integrity and aesthetics over time while minimizing maintenance cost and maximizing the sustainable aspect of the overall construction project.

Due to innovations in the manufacturing processes of aluminum shape—especially in extrusion and CNC bending—it is now simpler and more affordable to generate curved profiles. As the processes to custom-manufacture increased, designers are able to have their specific visions realized without compromising, and most importantly, without precisely conforming to available standard materials. As technologies for the producing become more efficient, the cost of the profiles decreases even more and the opportunity for the designer to consider them becomes more commonplace.

In conclusion

Curved aluminum profiles will be a key part of the future of architecture and construction. As they are seen as a versatile, strong, and visually-parts-driven solution are an important material choice for designers and engineers with vision. As the construction sector embraces innovation and sustainability curved aluminum profiles will drive future change and unlock new designs and infrastructure.