-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

Durability and Design: The Versatility of Aluminum C Profiles

2024-12-13

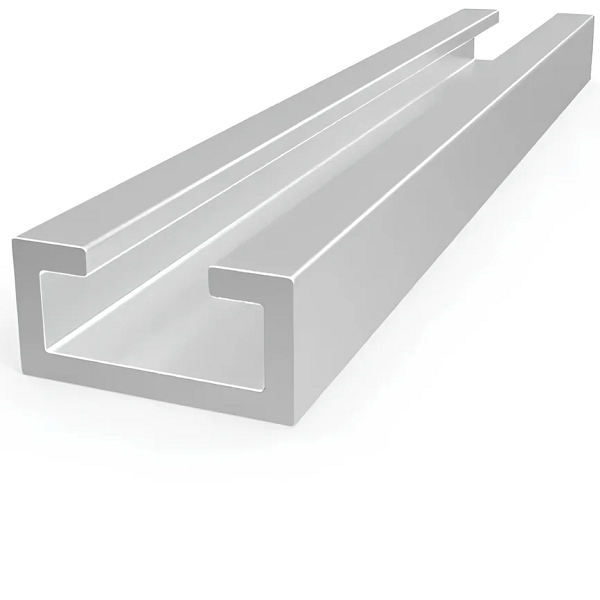

Aluminum C profiles have perfect applications in the fields of architecture, engineering and manufacturing for the simple reason that they combine durability, lightweight properties and design versatility.

These profiles, also commonly known as “C channels” or “C beams,” are made from high-quality aluminum, which boasts a great strength-to-weight ratio, corrosion resistance, and is easy to fabricate. From structural uses to aesthetic designs, aluminum C profiles provide a wide range of uses, making them indispensable in many industries, from construction to automotive and even aerospace.

The Physical Properties that Enhance Durability

The inherent durability of aluminum C profiles is a major factor in their widespread use in construction. Aluminum can be used both indoors and outdoors without deteriorating under continuous exposure to moisture, UV radiation, and other environmental conditions because it naturally resists corrosion by forming an oxide coating when it comes into contact with oxygen.

Aluminum not only resists corrosion but also maintains robust structural integrity while being comparatively lighter than other metals like steel. Aluminum C profiles are perfect for heavy-duty applications and situations where weight reduction is crucial because of their strength and lightweight.

Aluminum is a great material for unique designs because of its malleability, which also makes it easy to form accurate and complicated profiles without sacrificing strength.

Versatility in Design and Application

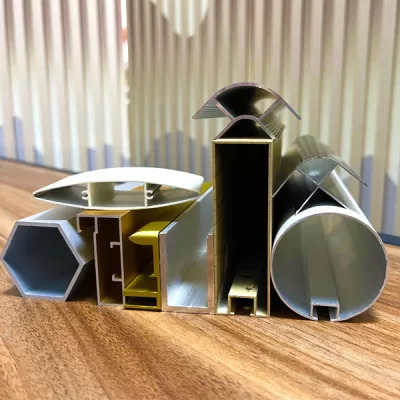

Aluminum C profiles come in a wide variety of sizes, thicknesses, and finishes to increase design freedom. The “C” shape is a narrow-throated, wide-flanged channel or beam that connects easily to other parts and offers structural support. This makes it very desirable for use in trusses, brackets, supports, frames, and even in the building of machinery, bridges, and structures.

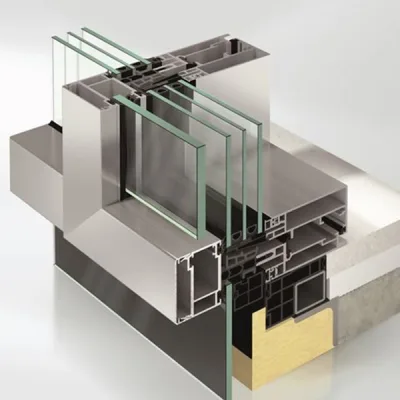

The versatility of aluminum C profiles is among their most popular benefits. They are used as structural components in a range of engineering and architectural applications, such as frames for residential and commercial buildings, where it is important to have load-bearing materials that are not as bulky as heavier ones like steel. Aluminum C profiles, for instance, are frequently used in window frames, roofing systems, and curtain walls because of their sleek, contemporary appearance, which adds strength and visual appeal.

In the automotive sector, aluminum C profiles find an ever-increasing use in vehicle chassis, structure, and even body panels. Because aluminum is lightweight, it helps reduce a vehicle’s total weight, which enhances performance and fuel efficiency. In addition, all of these parts will have a long service life despite exposure to adverse weather conditions because of their resistance to rust and corrosion.

In aerospace, where both weight and strength are critical, aluminum C profiles are often utilized in aircraft frames and structural supports. Aluminum is the preferred material for the aircraft industry because of its excellent strength-to-weight ratio and resistance to high pressure and temperatures.

Ease of Fabrication and Sustainability

The ease of fabrication is also greatly appreciated in aluminum C profiles. Compared to other metals, the material is pretty easy to work with, which allows for rapid production times and ultimately reduces manufacturing costs.

High precision can be achieved in the extrusion of even complicated shapes, making the metal a very good fit for applications with important design elements. Besides, it can easily be welded, machined, and even anodized or powder-coated to give it an impressive appearance and additional protection against environmental factors.

Another significant advantage of aluminum C profiles is their sustainability. Aluminum is one of the most recyclable materials on earth, and recycling aluminum uses only a fraction of the energy required to produce new aluminum from raw materials. Because it lessens a project’s environmental impact, aluminum is therefore a very sustainable material for manufacturing and building.

Conclusion

Aluminum C profiles’ unparalleled strength, durability, and adaptability make them essential in a wide range of applications. Their sustainability and recyclability guarantee that they support ecologically conscious building practices, and their resistance to corrosion, lightweight nature, and ease of manufacture enable creative design ideas.