-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

Exploring CNC Aluminum Profile Bending for Precision Projects

2024-11-18

CNC aluminum profile bending is one of the most advanced technologies in today’s manufacturing processes. It enables multiple industries to manufacture precise and complex parts, including car body components, aircraft parts, construction, and furniture.

The process offers flexibility, accuracy, and durability. With the growing demand for customized high-quality aluminum parts, CNC aluminum profile bending is becoming more and more popular.

What Is CNC Aluminum Profile Bending?

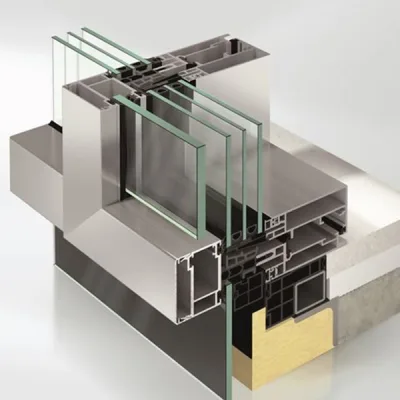

CNC (Computer Numerical Control) aluminum profile bending involves the utilization of advanced machinery to bend aluminum extrusions into specific shapes and angles. This process is guided by computerized systems that control the machine applied in the bending, ensuring every operation is as precise as the specifications for every detail.

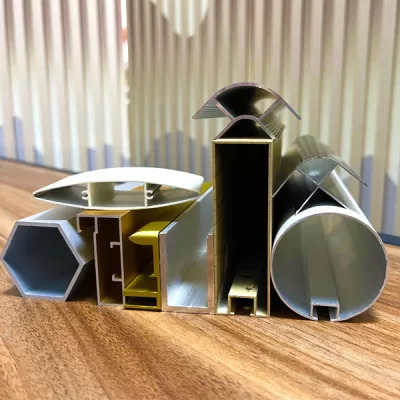

Aluminum profiles, often chosen for their lightweight yet robust properties, are bent without compromising their structural integrity, thus making them suitable for use in applications that require both form and function.

The process starts with a detailed design fed into the CNC machine, usually in the form of CAD (Computer-Aided Design) files. These instructions are then translated by the machine into very precise movements and the aluminum profile is bent by using rotary stretch bending, mandrel bending, or roll bending. Each technique would be chosen based on the profile’s shape, wall thickness, and the required bend radius.

Advantages of CNC Aluminum Profile Bending

What CNC bending machines do best is offer ultimate precision. Each bend is exactly made as specified and replicated identically to every other bend of its kind, which might be of paramount importance in industries like aerospace, where even slight deviations can result in huge problems.

CNC technology can also provide complicated shapes and designs of parts with difficult curves and angles. Whether simple arc or multi-dimensional form, CNC bending allows the feasibility of practically any design.

The automation involved in CNC systems makes them hardly prone to human errors, accelerates production, and reduces waste of materials. Considering these factors, it is cost-effective for both small-scale and large-scale projects.

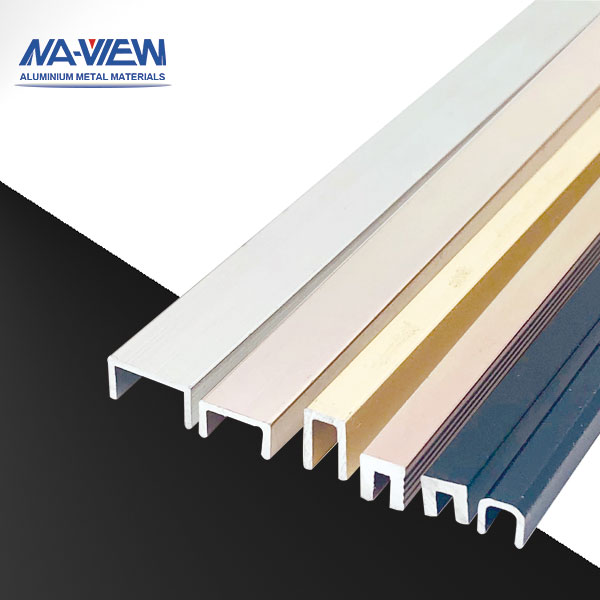

Unlike other conventional methods of bending, CNC bending has minimal stress points, hence reducing or eliminating the possibility of cracks or deforming. Therefore, in this way, the service life and reliability of the profiles can be guaranteed even when working under harsh conditions. This is especially true when using Naview aluminum profiles, ensuring superior results in CNC bending applications.

In addition, the precision of CNC bending means less material waste, contributing to environmentally friendly manufacturing practices. Aluminum is also recyclable, making this process consistent with sustainable development goals.

CNC Aluminum Profile Bending: Challenges and Solutions

While CNC aluminum profile bending offers numerous benefits, it comes with challenges, particularly when dealing with intricate designs that are very complex or the radius is very small. For example, when the wall of the aluminum profile is very thin, it is easy to have wall buckling or distortion. This issue can be mitigated through techniques like mandrel support, which provides internal reinforcement during the bending process.

Another challenge is maintaining dimensional accuracy over long bends, especially with large or complex profiles. This requires advanced calibration and the use of high-quality tooling to prevent deviations.

As technology advances, the future of CNC aluminum profile bending looks promising. With the integration of artificial intelligence and machine learning, greater precision and efficiency can be envisioned as it allows machines to adapt and optimize processes in real-time.

Conclusion

CNC aluminum profile bending is becoming more and more important in modern manufacturing. It is a very precise, versatile, and efficient process, therefore indispensable in industries that need high-quality, custom components. The technology will be further developed and the potential applications and benefits of CNC bending will expand, driving innovation and sustainable development in large-scale manufacturing projects around the world.