-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

Exploring the Technology Behind China Aluminum Profile Powder Coating Lines

2024-12-27

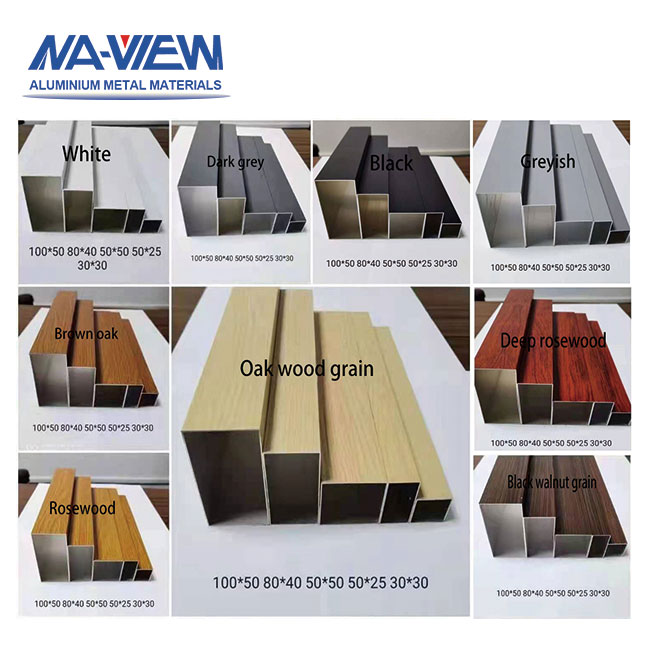

In recent years, China has emerged as a global leader in manufacturing aluminum profiles, offering high-quality products across various industries. A key factor behind the success of China’s aluminum manufacturers is the advanced powder coating technology used in the production of aluminum profiles. Powder coating is a highly effective and environmentally friendly finishing technique that enhances the durability, aesthetic appeal, and corrosion resistance of aluminum surfaces.

What is Powder Coating?

Before going into the specifics of the China powder coating lines, an understanding of what powder coating is and why it finds such favor for aluminum profiles should be gained. Powder coating is a dry finishing process that utilizes fine, dry powder, usually made from resin, pigment, and additives, which is electrostatically applied onto a metal surface. The item being coated is then baked under high heat in an oven, which causes the powder to melt and flow into a tough, durable finish.

The benefits of powder coating over traditional liquid painting include better coverage, improved durability, and a more environmentally friendly process. There are no solvents within the powder, which greatly reduces emissions and volatile organic compounds. This creates a relatively environmentally friendly procedure that would appeal to most manufacturers that are keen on minimizing their ecological footprint.

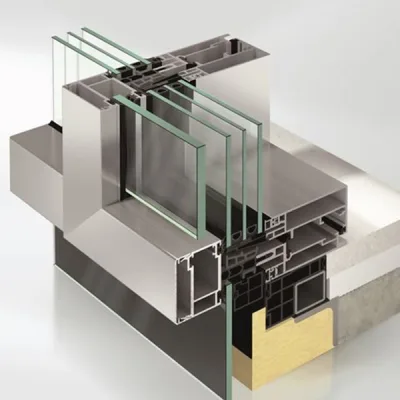

Key Components of a China Aluminum Profile Powder Coating Line

The China aluminum profile powder coating lines are well-considered in design for efficiency, automation, and precision. Therefore, the production line includes a number of key stages, including:

Pre-treatment Station: This stage prepares the surface by removing oils, dirt, and oxidation from the aluminum profiles. It typically includes chemical cleaning, acid etching, and rinsing. This step is necessary to create the right conditions for adherence of the powder onto the aluminum surface.

Powder Application System: After pre-treatment, the profiles are moved to the powder application station where electrostatic spray guns ensure uniform application of the powder on the profiles. In most modern coating lines in China, both automated spray guns and robotic systems are installed for accurate application.

Curing Oven: The coated profiles then go through a curing oven, where they are heated at temperatures between 160°C and 200°C. This melts the powder, which then flows and bonds to the surface, creating a solid, durable finish. The curing also enhances the chemical and mechanical properties to ensure resistance to wear, corrosion, and environmental damage.

Cooling and Quality Inspection: The profiles, after curing, are cooled down and then sent for quality checking. Automatic systems find defects in uneven coating or color mismatch. Besides, there are manual checks at the end to ensure the finished profiles are up to the mark.

Conclusion

China aluminum profile powder coating lines symbolize the latest finishing technologies, bringing automation, state-of-the-art electrostatic application, energy-efficient curing, and sustainability together. It is this evolution of systems that has allowed China to remain one of the world leaders in the production of aluminum profiles, offering quality and durability but also a very important aesthetic appeal.

As advancements continue in this area, China will likely continue to be at the forefront of the powder coatings industry, meeting the needs of global customers while achieving environmental and economic sustainability.