-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

How Aluminum Alloy Profiles Are Transforming the Automotive Industry

2024-12-19

Recent years have seen a dramatic shift in the automobile sector, with a greater focus on innovative production processes, fuel efficiency, and sustainability. The growing usage of aluminum alloy profiles in vehicle building is among the most significant advancements in this evolution.

These specialized profiles, which are precisely shaped forms of aluminum, are playing a crucial role in reshaping the design, performance, and environmental footprint of modern vehicles.

The Rise of Aluminum Alloy Profiles in Automotive Manufacturing

Aluminum has long been utilized because it is lightweight and corrosion-resistant, and its use in automotive applications has grown with the introduction of aluminum alloy profiles.

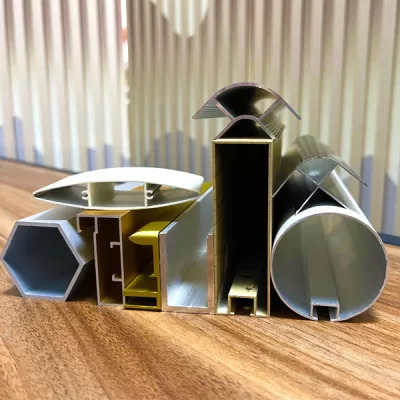

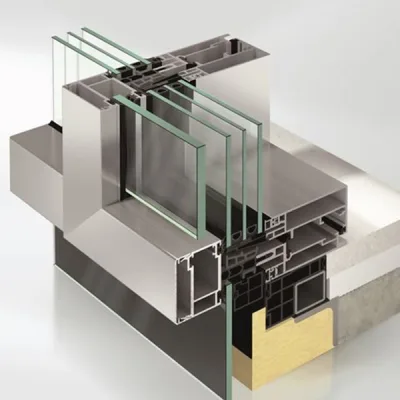

In contrast to pure aluminum, aluminum alloys are made by combining aluminum with additional metals including silicon, copper, and magnesium. These alloys maintain the crucial advantages of lightweight and corrosion resistance while exhibiting exceptional strength and endurance. They are therefore being utilized more and more in body panels, car frames, and other important structural elements.

Steel used to be the main material used to make vehicles since it was easy to make and robust. However, manufacturers are now turning to lighter materials like aluminum, which can reduce the overall weight of vehicles and improve fuel economy without sacrificing safety or performance, in order to meet stricter emissions standards and increase fuel efficiency.

Enhancing Fuel Efficiency and Performance

Aluminum alloy profiles are widely used in the automotive industry because they have the potential to greatly increase fuel efficiency. Better economy and fewer greenhouse gas emissions are the results of the manufacturer using less energy to propel the car due to the vehicle’s decreased weight.

The benefits of aluminum for electric vehicles (EVs) are even more obvious. Because of the size and weight of the batteries, EVs are inherently heavier due to their reliance on battery power. Automakers can partially counteract the weight by using aluminum instead of heavier materials, increasing the range and efficiency of electric vehicles.

Improving Safety Without Compromising Design

While reducing weight is crucial for fuel efficiency, safety is always the first consideration when designing a vehicle. Because of their excellent strength-to-weight ratio, aluminum alloy profiles are especially well-suited for strengthening important structural components like safety cages and chassis. Vehicles made from aluminum alloys have performed exceptionally well in crash tests, absorbing significant impact energy while shielding occupants from injury.

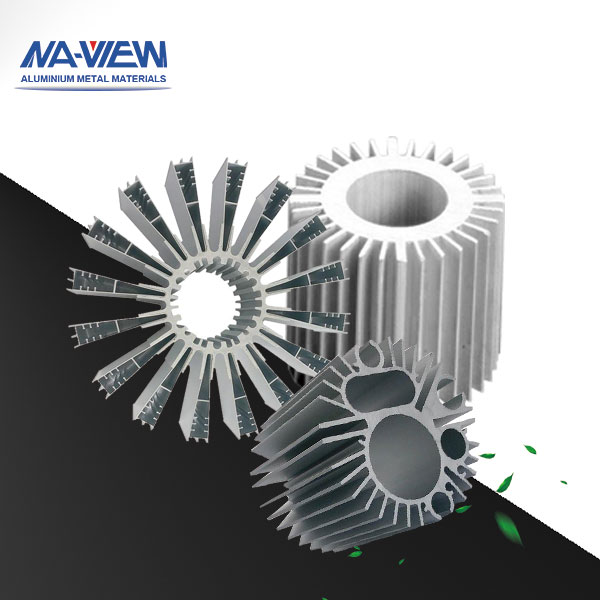

Furthermore, because aluminum alloys can be molded and formed into intricate profiles that were previously impossible or difficult to do with conventional materials, they enable more creative designs. Because of this adaptability, automakers can produce lighter, more aerodynamic cars without sacrificing structural integrity or safety.

Sustainability and Recycling

Besides performance and safety, aluminum alloy profiles also have very impressive sustainability. Aluminum is 100% recyclable, with the energy usage to recycle being a fraction of what is needed to produce new aluminum from raw materials.

Over 75% of all aluminum ever produced is still in use today, thanks to its recyclability. What this means to automakers is that not only can vehicles be constructed using sustainable materials, but at the end of their life, they can be recycled into new components for future models.

Conclusion

Aluminum alloy profiles are playing a key role in the transformation of the automotive industry. Their ability to reduce weight, enhance fuel efficiency, improve safety, and contribute to sustainability makes them an indispensable material in the design and manufacturing of modern vehicles. As the industry continues to evolve, aluminum alloy profiles will remain at the forefront of innovation, driving the future of transportation toward a more sustainable and efficient future.