-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

How Aluminum Profile Connectors Simplify Complex Assembly Processes

2025-01-03

Aluminum profile connectors have become one of the essential elements in modern manufacturing and construction processes, especially when it comes to the preparation of customized frameworks, machinery, and industrial structures.

This has dramatically changed the concept of assembly and drastically reduced production time. Aluminum profile connectors offer versatility, efficiency, and cost-effectiveness support industries in streamlining operations and achieving more flexible designs.

Versatility and Customization

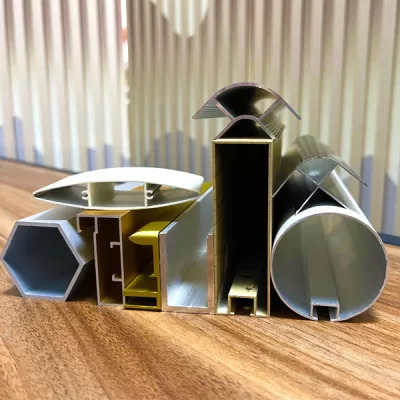

The versatility of aluminum profile connectors is the reason why assembly is quite easy. These connectors work with some aluminum extrusions such as T-slot, square, and rectangular sections. This allows for everything from simple shelving units to complex industrial frames.

Besides, most of the aluminum extrusions are with a standardized T-slot system, which is compatible with a wide range of connectors and fasteners. These T-slots allow for easy insertion of components like brackets, joints, and connectors, making assembly much faster and more precise.

Simplification of Assembly

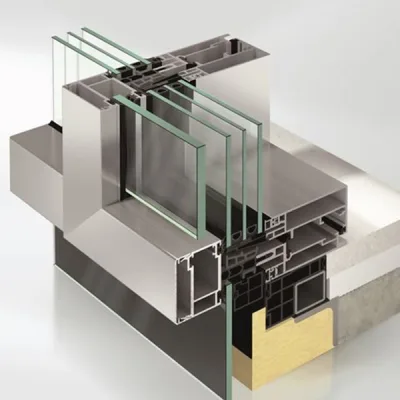

Most conventional methods of assembly, such as welding or bolting parts together, have a number of complex steps that require proficiency. For instance, welding might be slow and sometimes require proper calibration and bolting might need hole drilling with fasteners. These are relatively simpler to handle in the case of aluminum profile connectors by means of mechanical joints that require no welding or heavy machinery.

These connectors use very simple fasteners like bolts, screws, and nuts, which are easy to mount with basic tools. In addition, because aluminum profiles are lightweight, they are easier to handle and assemble compared to heavier materials, further reducing labor costs and assembly time.

Cost Efficiency

The cost benefits of using aluminum profile connectors are also significant. During the assembly of structures, there is hardly any need for custom-built components or precision-cut parts. Instead of having to outsource custom parts or tools, manufacturers can use standardized aluminum profiles and connectors to reduce special equipment or expertise requirements by a huge margin. Labor costs are lower because assembly times are shorter, and less technical skill is required.

Moreover, aluminum itself is an affordable and sustainable material, making it an attractive option for companies focused on cost management and eco-friendliness. Aluminum profiles can be reused or reconfigured multiple times, which adds to their overall cost-effectiveness.

Ease of Modification and Maintenance

Other advantages to working with aluminum profile connectors include the fact that structures can easily be changed or reconfigured. When adjusting business needs, systems or machines often need to be updated, and changes are easily and quickly made when dealing with an aluminum profile. A simple adjustment, such as adding or removing a profile or connector, can greatly affect the dimensions or functionality of the structure without having to incur costly redesigns.

Besides, it allows for easier maintenance and repairs. Sometimes, if a part of the frame or structure needs to be replaced or adjusted, it can be simply done by replacing one connector or profile instead of redoing an entire assembly.

Conclusion

Aluminum profile connectors make complex assembly processes very simple due to their versatility in assembly, cost efficiency, and flexibility in design. Whether for construction, automation, or other industrial applications, connectors enable the construction of strong and customized frameworks quickly and reliably. Combining practicality with innovation, aluminum profile connectors will become a valuable tool in modern manufacturing and assembly.