-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

How to Calculate Aluminum Profile Cost for Your Projects

2025-04-29

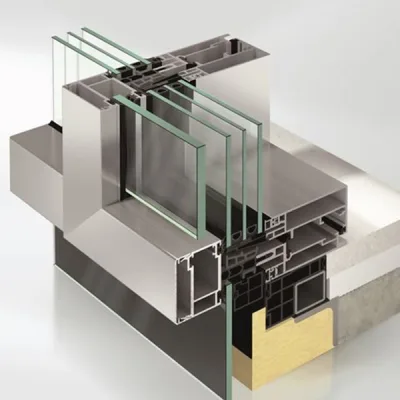

If you’re working on a project which needs you to source special aluminium profiles, one of the first things you’ll need to know is how to accurately cost your project. Because aluminum profile has the advantages of industrial maintenance, lightweight, and corrosion resistance, it is widely used in construction, furniture, and even equipment manufacturing. But it is important to know what influences the cost if you want to budget correctly for a project. In this post, we are going to break down how to calculate costs for aluminum profile manufacturing.

Influencing Factors Of Aluminum Profile Price

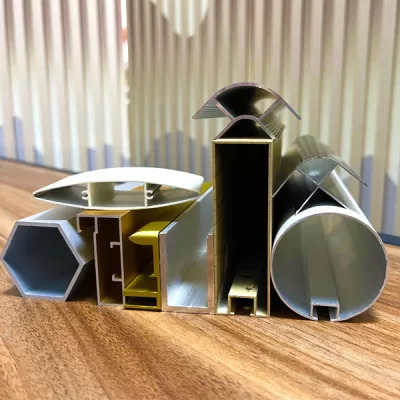

The price of aluminum profiles can fluctuate, depending on several factors. First of all, it is the type of material that has a huge impact. A variety of other alloys are available, including (but not necessarily limited to) 6061 or 6063, which provide differing strength and durability characteristics, the most durable of which are also the most expensive. Also, finishing (anodizing, powder coating, or plain) can cost more, with finished profiles generally more expensive because they need extra processing.

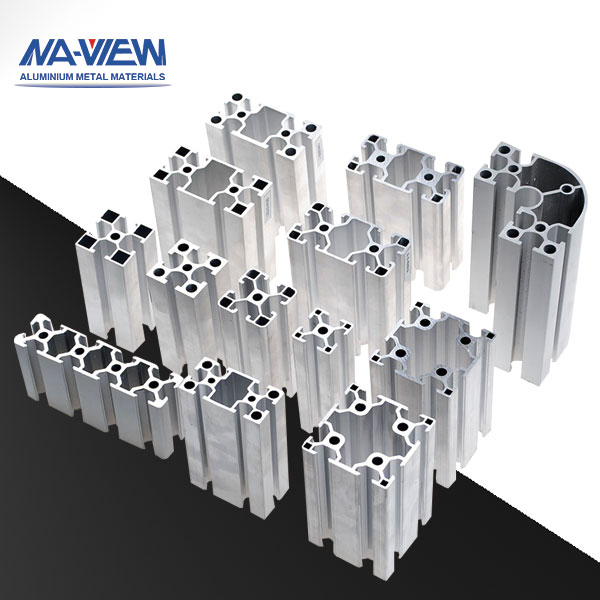

A further aspect is the pattern configuration. Tailor-made profiles are, however, more expensive than mass-produced profiles. Profile length and dimensions also influence price—longer or wider profiles are usually more expensive as they require more material to be used and more advanced production methods.

And if you’re ordering in bulk, this can really chip away at the price per unit. Suppliers often extend volume discounts, so purchasing in bulk can be the way to go. But bulk orders have to be mixed with actual project demand, or there will be overstock.

The manufacturing process can also factor into the cost. Profiles made via the extrusion process, including recoil-cut profiles, for example, are popular and can be economical to produce. On the downside, if the profiles need special molding or machining, there will also be a cost.

Lastly, all delivery and shipping costs can add up. Depending on where you are and who you’re buying from, distance and logistics can really add up to a lot of the total price, especially if you’re importing from another country.

How To Calculate The Cost of Aluminum Profile

To determine aluminum profile price accurately, it’s recommended to go through the following steps:

Know What You Need For Your Project: The first step to finding the right aluminum profiles is to get a clear understanding of the size, material, and design requirements of your project. Are they standard dimensioned or custom? Do you require anodized finishes or certain alloys? The more specifically you outline what you want in your project, the more accurate an estimate you can receive.

Get Price Per Unit: Reach out to distributors or online platforms to find out how much your specific units are costing at the moment. Costs may fluctuate depending on market demand, so it’s a good idea to get quotes from more than one supplier.

Multiply by Quantity: After getting the price of one profile, multiply it with the total quantity you require for your project. This is your base price for your materials.

Add Extra Costs: Don’t forget to factor in any additional fees for shipping, cutting, or custom shots. For instance, if profiles will be cut to lengths or there’s any assembly and finishing work required, these will all add costs.

Conclusion

The accurate estimation of the aluminum profile cost for your project is key to keeping it under budget and to completing it to a high-quality standard. Material type, design, manufacture, and shipping—all these can be factored in to give you an accurate idea of the overall costs. Just do the work and break them into their component parts, and shop around for the best prices for those things–it can save you a lot of money and lead to better project outcomes in the longer view.