-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

Understanding the Process and Applications of Aluminum Profile Extrusion

2024-11-15

Aluminum profile extrusion has become a very significant process in modern manufacturing. It offers great flexibility in producing complex, lightweight, durable components across different industries. The process will turn aluminum alloy into specific profiles with extreme precision, offering unparalleled flexibility in design and application.

The Process of Aluminum Profile Extrusion

Extrusion begins with the preparation of aluminum alloy billets. These billets are heated within a temperature range of between 750°F to 925°F, that is, 400°C to 500°C, a temperature at which the alloys become ductile while still retaining their fundamental properties. When the billet has attained the desired temperature, it is then loaded into an extrusion press.

Inside the press, a hydraulic ram forces the billet through a die, an opening cut in the desired profile. As the aluminum extrudes from the die, it assumes an exact shape of the die cross-sectional shape. The structural integrity of the aluminum extrusion is retained subsequently with cooling by either air or water.

After cooling, the extruded profile is straightened and cut to length as desired, besides subsequent processing steps for surface improvement and appearance, such as anodizing, powder coating, or machining.

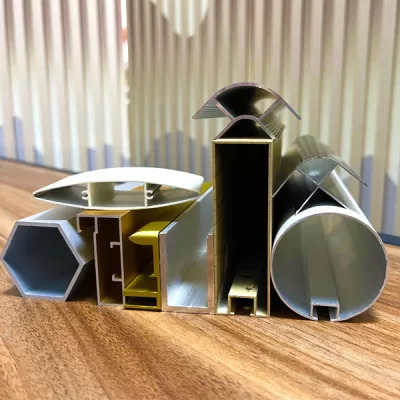

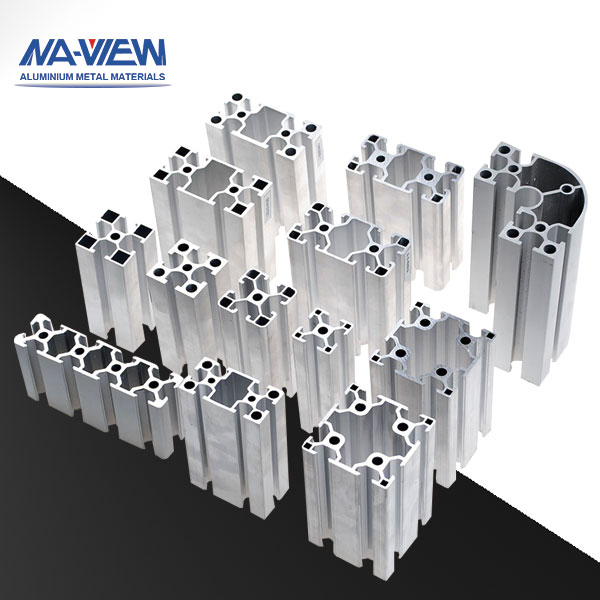

Modern extrusion technology enables the manufacturing of complex shapes of hollow, semi-hollow, and solid profiles with close tolerances and fine surface finish. Computer-aided design and precision engineering have now allowed the manufacture of special dies, serving specific needs in many applications.

Advantages of Aluminum Extrusion

The properties of aluminum make it suitable for extrusion. Lightweight and strong, aluminum offers structural strength without adding weight unnecessarily. It resists corrosion and is ideal for outdoor and industrial use. Its excellent thermal and electrical conductivity enhances its utility in specialized applications, such as heat sinks and electrical enclosures.

In addition, aluminum is an environmentally friendly material that is 100% recyclable without losing its quality, helping to reduce the impact on the environment. Extrusion is an energy-saving process compared to other methods of fabrication, which makes it cost-effective, too.

Application of Aluminum Profile Extrusion

Extruded aluminum profiles find applications in various fields due to the advantages of their adaptability and functionality. Some key sectors and applications are as follows:

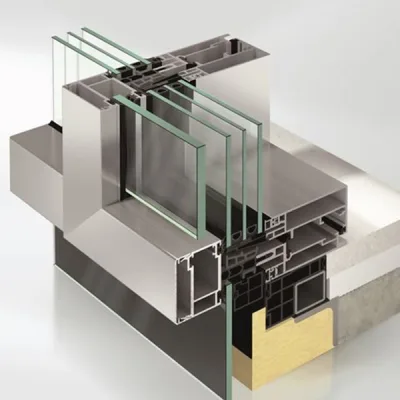

Construction and Architecture: Aluminum profiles find their application in a number of ways in building facades, window frames, door frames, and curtain walls, offering corrosion resistance and design flexibility. In addition, they are structurally used as load-carrying beams and frames. The high ratio of strength to weight in aluminum provides strength and reliability with no excessive weight.

Transportation: Aluminum extrusions in automotive, aerospace, and rail applications can reduce weight, which is key to improving fuel efficiency and reducing emissions. Extruded aluminum profiles are used in cars for the manufacture of chassis components, roof rails, crash management systems, heat exchangers, and interior trims.

Electronics and Electricals: Extruded aluminum heat sinks contribute to dissipating heat generated in every electronic gadget, starting from LED lighting up to power systems. Casings and housing made of aluminum protect sensitive electronic equipment and guarantee electromagnetic compatibility.

Renewable Energy: Extruded aluminum finds its other use in the manufacture of mounting systems and frames of solar panels on account of its resistance to weather conditions and strength. Other applications in the wind energy sector include components like nacelle frames, housings, and turbine blades, where extruded aluminum profiles are applied.

Conclusion

Aluminum profile extrusion is a cornerstone of modern manufacturing, delivering efficient, customizable solutions for a range of industries. Its advantages of strength, lightweight nature, corrosion resistance, and recyclability have made the material indispensable in today’s drive toward sustainability and innovation. Aluminum extrusion will shape the future of design and functionality in many applications as technology continues to evolve.