-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

The Versatility of Industrial Aluminum Profiles in Modern Manufacturing

2025-01-02

With the continuous development of modern manufacturing, the demand for materials with strength, lightness and flexibility is on the rise, which ultimately greatly increases the popularity of industrial aluminum profiles. This makes aluminum, a versatile and effective material, finds its way into almost all key sectors, from automotive and aeronautics to building and electronic industries.

Lightweight Strength and Durability

One of the most important reasons for the popularity of aluminum profiles is their unique combination of lightweight properties with an impressive strength-to-weight ratio. Aluminum is much lighter compared to a lot of other metals, and this factor is very important in applications where weight reduction is of primary importance, such as the automotive and aerospace industries.

Besides its lightness, aluminum retains the properties of durability, corrosion resistance, and structural integrity. These make it effective for use in aluminum profiles under harsh conditions without losing strength.

Customizability and Design Flexibility

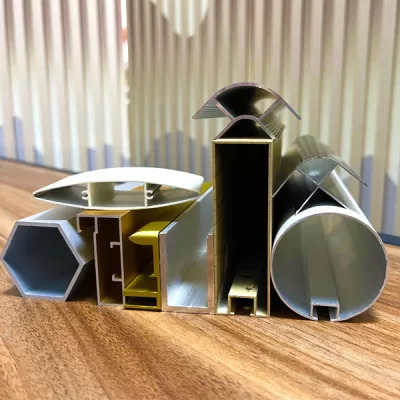

The other major advantage of aluminum profiles is the great flexibility in design. These profiles can be extruded in many different shapes and sizes, thereby making them highly customizable for specific project requirements.

Aluminum profiles can be designed to extremely precise specifications, allowing the creation of highly useful and efficient components, whether they are needed for framing, structural supports, enclosures, or other applications. This versatility not only makes a variety of applications possible, but also helps to improve design process efficiency, guaranteeing that materials are used efficiently and with little waste.

Aluminum profiles are more versatile than just their shape and form. Additionally, surface treatments like painting, powder coating, and anodizing make it simple to alter them. All these treatments can strengthen the material’s resistance to corrosion and wear and provide aesthetic appeal. To put it another way, aluminum profiles can satisfy both aesthetic and performance requirements.

Sustainability and Environmental Benefits

Aluminum is a highly recyclable material that can be reused in several ways without losing its characteristics. Moreover, recycling aluminum requires only a small fraction of energy when compared to the requirement for primary production, thus considerably decreasing the environmental impact of the manufacturing process.

Besides, durability makes products produced with aluminum last longer and eliminates the need for frequent replacement and repair. This also provides an end product that can achieve a more sustainable life cycle and minimize environmental impact in the long term.

Wide-Ranging Applications

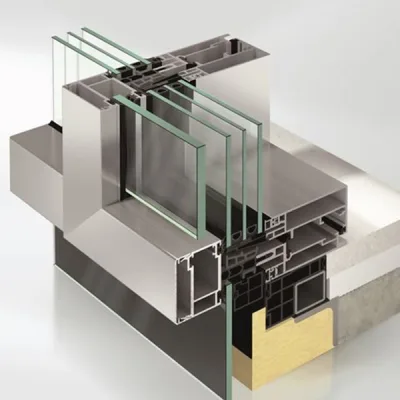

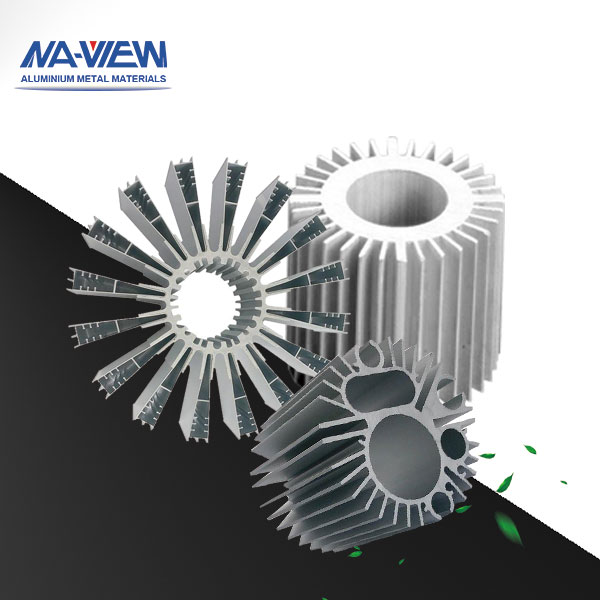

The applications of aluminum profiles are immense and varied. They find their application in the building industry for window frames, curtain walls, and façades because they can bear the weathering elements with slender appearances that are modern in appeal. In the electronics industry, aluminum profiles perform heat dissipation processes essential for different equipment, including computers, LEDs, and power supplies, so these cannot overheat and face issues to perform better.

Aluminum profiles used in the automotive sector can lighten the weight of a car to enable fuel efficiency and reduce harmful emissions while not compromising safety or strength. The same characteristics are useful in aerospace industries where lightweight yet strong aluminum profiles play a vital role in aircraft parts that require performance with minimum weight.

Conclusion

The versatility of industrial aluminum profiles significantly affects modern manufacturing in a number of diversified industries. Their value is unmatched due to their vast range of applications, sustainability, design flexibility, and lightweight strength. Aluminum profiles are probably going to stay at the forefront of cutting-edge manufacturing solutions for years to come as industries continue to place a high priority on performance, efficiency, and environmental responsibility.