-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

Top Reasons to Use Aluminum Square Profiles in Manufacturing

2024-11-26

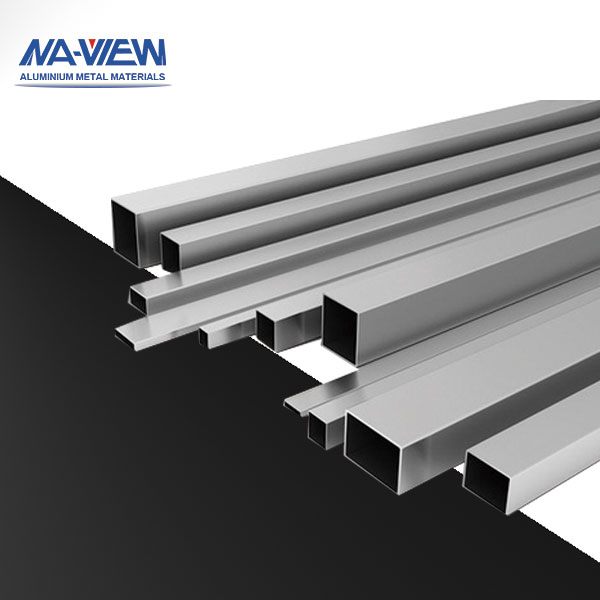

In manufacturing, aluminum square profiles are not only a versatile option, but also a design innovation. Their square shape makes them widely used in various industries. Combining the inherent properties of aluminum with the advantages of a square geometry, these profiles offer a balance of strength, functionality, and efficiency that is difficult to match.

Structural Integrity of the Square Shape

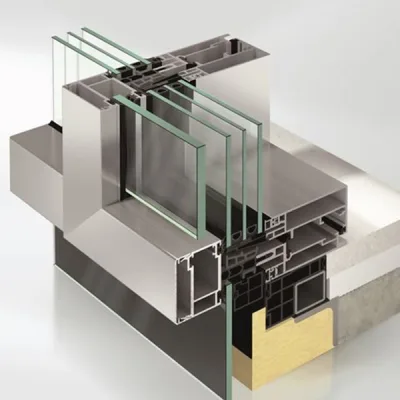

The square shape of aluminum profiles is inherently strong and balanced. Round or irregular profile shapes do not provide the same uniform strength as the four sides of a square. This uniformity ensures they bear loads uniformly, ideal for structural applications in the building and construction, frameworks, and support systems.

The corners of the square profile add rigidity to it. With the stress well distributed, square profiles resist deformation much better compared with other geometries like circular or flat profiles. This is also an essential feature when designs require long spans or heavy-duty support structures, like shelving systems, bridges, or industrial frameworks.

Maximized Load-Bearing Capacity

The square shape has a higher moment of inertia for the same material and weight compared with other shapes, which directly translates into superior load-bearing capacity.

Because of this, projects that demand strength and durability find aluminum square profiles to be a necessity. They can be used in the manufacture of conveyor systems, scaffolding, and machine frames, as their square shape ensures the structure will be strong and secure even under dynamic loads.

Flexibility in Design and Assembly

The flat surfaces of aluminum square profiles make them very easy to work with in design and assembly. Their geometric simplicity enables straightforward connections to other components, without complex tools or fittings. Manufacturers can easily drill, weld, or bolt aluminum square profiles together, enabling fast processes of prototyping and assembly.

Also, the flat sides allow for accurate alignment, a very valuable feature in constructing modular or adjustable systems. For instance, in furniture manufacturing or modular building frameworks, the square shape makes the assembly much easier while still holding precision.

Efficient Use of Space

The square geometry of these profiles allows them to mesh perfectly, thereby optimizing space utilization. This feature is incredibly helpful in applications dealing with shelving, racking, and storage systems where space is of the essence. Unlike cylindrical profiles that will have gaps while being stacked or joined, square profiles leave minimal wasted space, adding to compactness and neatness in designs.

Aluminum square profiles can also be hollow or solid, depending on the application. Square hollow profiles bring more advantages in that they provide the necessary strength while being lightweight and allow for space-saving, which is important in industries related to aeronautics and transportation.

Customization and Modular Applications

Aluminum square profiles are widely used in modular manufacturing systems, thanks to their adaptability and ease of customization. The uniform square shape allows manufacturers to create standardized designs that can be easily expanded or reconfigured. This modularity is particularly valuable in industries like renewable energy, where aluminum square profiles are used in solar panel frames and wind turbine structures.

Moreover, the square shape allows for the incorporation of accessories like connectors, joints, and fasteners. Many of these accessories are designed only for square profiles, which increases their versatility even more and makes them a favorable option for systems that need to be scalable.

Conclusion

The shape of the aluminum square profiles is what puts them into widespread use in manufacturing. Their uniformity, strength, and adaptability make them a versatile solution for a variety of applications.

The advantages in structure and design offered by the square shape allow manufacturers to create products that are functional, durable, efficient, and aesthetically pleasing. From modular systems and architectural frameworks to industrial equipment, aluminum square profiles demonstrate how the right geometry can enhance the potential of a material.