-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

What is Aluminum Profile and Why is It Essential in Modern Construction?

2024-11-22

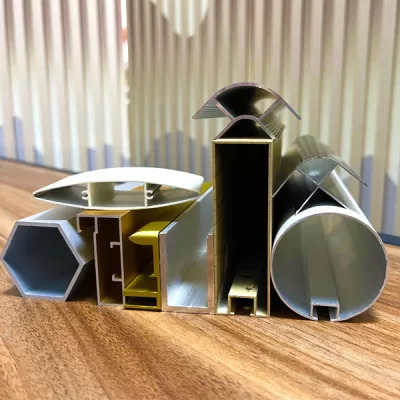

Aluminum profiles, also known as aluminum extrusions, are versatile components broadly used in modern construction for their durability, lightweight, and adaptability. They are produced through a manufacturing process called extrusion, where aluminum is heated and forced through a die into a specific cross-sectional shape. These profiles can therefore be tailored to the different needs of their application, from structural frames to aesthetic elements.

Properties That Make Aluminum Profiles Stand Out

One of the main reasons aluminum profiles are indispensable in construction is their unique combination of properties. Aluminum is inherently lightweight, making it simpler to transport and install than traditional materials such as steel or wood. Although it is light, it is strong and can withstand large loads, so the structural support is reliable.

Aluminum also offers very good resistance to corrosion due to the natural oxide layer formed over it, which acts protectively against environmental factors such as moisture and air. This attribute can prolong its service life while cutting maintenance costs. This is why it is also preferred outdoors in the form of curtain walls, windows, and cladding. Additionally, aluminum is recyclable, making it an eco-friendly material that aligns with modern sustainability goals in construction.

Applications in Modern Construction

Aluminum profiles find wide applications in both residential and commercial projects due to their versatility and appealing looks. Some major fields where they have become quite indispensable include the following:

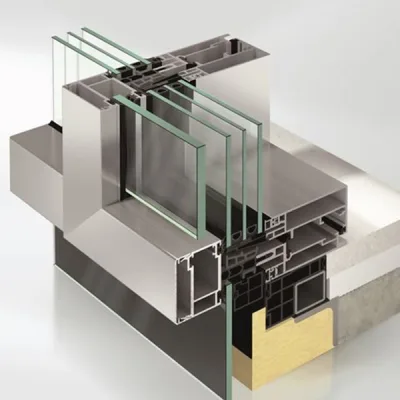

Architectural Frameworks: Aluminum profiles in the building industry are widely used for the construction of doors, windows, and curtain walls. Their ability to support large glass panels while maintaining structural integrity makes them a preferred choice in modern architecture, especially for high-rise buildings.

Structural Support: Due to their strength-to-weight ratio, aluminum profiles are utilized in load-carrying constructions: beams, columns, and trusses. They are often designed for specific needs to ensure optimal performance without adding unnecessary weight.

Cladding and Facades: Aluminum cladding is in high demand because it is durable and resistant to inclement weather conditions. Besides that, it gives a modern, polished look, and that is one of the reasons it’s a favorite for exterior facades.

Interior Applications: The application of aluminum profiles is not restricted to the outdoors. Interior design elements include partitions, ceiling panels, and decorative features. Their versatility allows designers to create intricate and modern layouts that complement various architectural styles.

Specialized Applications: Besides conventional construction, aluminum profiles are applied in modular construction systems, prefabricated buildings, and solar panel mounting systems. Due to their precise fitting and ease of assembling, they find an excellent range of applications in these innovative uses.

Advantages in Construction Projects

The increasing demand for aluminum profiles in the construction industry is driven by several advantages they offer:

Design Flexibility: The extrusion process can provide complex and customized shapes, allowing architects and engineers to practically realize their creative ideas without sacrificing functionality.

Ease of Fabrication: It is easy to cut, weld, and assemble the aluminum profiles, which reduces the labor time and cost on the site.

Thermal Performance: Modern aluminum profiles can be fitted with thermal breaks to enhance energy efficiency, an essential factor for sustainability in construction.

Cost-Effectiveness: The initial cost of aluminum may be higher compared to some materials, but the low maintenance and long life expectancy offset this cost over time for a more cost-effective solution.

Conclusion

Aluminum profiles have revolutionized modern construction, offering a blend of functionality, durability, and aesthetic appeal. Their unique properties and wide range of applications make them a cornerstone of architectural innovation. As the industry continues to evolve, aluminum profiles will remain a vital component, driving sustainable practices and enabling the creation of iconic, long-lasting structures.