-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

What You Need to Know About Aluminum Profile Types and Standards

2024-11-22

Aluminum profiles are central in contemporary manufacturing, architecture, and engineering due to their strength, versatility, and lightweight properties that make them stand out in a variety of industries. Understanding the different types of aluminum profiles and standards governing their use is essential for making informed decisions in design and application.

Types of Aluminum Profiles

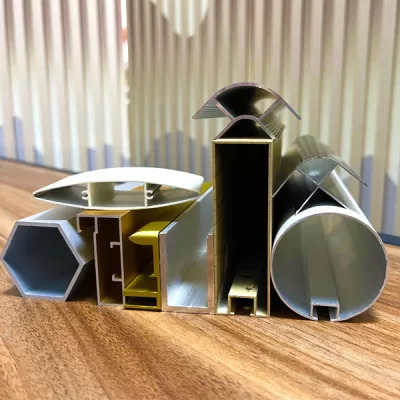

Aluminum profiles can be classified based on their cross-sectional area, purpose, and specific manufacturing method. The main types are as follows:

Standard Profiles: These are the most widely used profiles, featuring basic shapes like angles, channels, T-sections, and I-beams. They are readily available in the market, serving general applications in construction, transportation, and machinery.

Custom Profiles: Designed to meet specific requirements, custom profiles are tailored to fit unique applications. Industries like aerospace, automotive, and electronics often require intricate shapes that standard profiles cannot accommodate. Customization allows manufacturers to optimize material use and improve functionality.

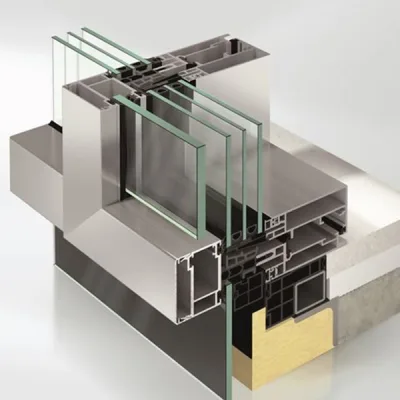

Structural Profiles: The structural profile is designed for high strength and good durability. Construction, heavy machinery, and load-carrying applications widely use structural profiles. This type of profile has to be designed to achieve a particular mechanical performance and is generally anodized or coated.

Modular Profiles: Modular profiles, such as those utilized in T-slot framing systems, can easily be assembled and reassembled with ease. Applications include building frameworks for workstations, conveyors, and automated systems. Their modularity makes them excellent choices for prototyping and flexible designs.

Heat Sink Profiles: The design of heat sink profiles allows for effective heat dissipation. These profiles play a critical role in electronic devices, LED lighting, and automotive applications where thermal management is crucial.

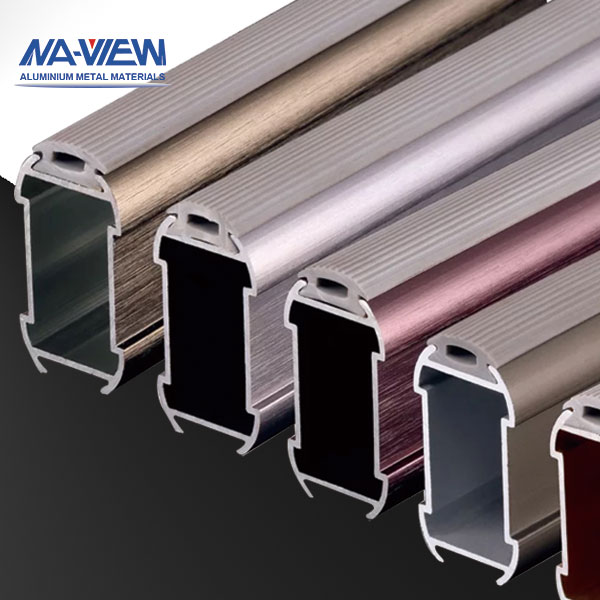

Decorative Profiles: Aluminum’s aesthetic appeal makes it ideal for decorative profiles, which find application in architectural detailing, furniture, and interior design. These profiles are usually anodized or powder-coated to produce a desired finish or color.

Standards Governing Aluminum Profiles

Standards make sure that aluminum profiles are produced with a guarantee of their quality, safety, and compatibility. They guide the manufacturer in the production of profiles with uniformity of dimensions, mechanical properties, and surface finishes. The important standards to know about include:

Material Standards: Aluminum alloys used in profiles are standardized by organizations like the Aluminum Association (AA) in the United States, the European Committee for Standardization (CEN), and the International Organization for Standardization (ISO). The two most commonly used alloys in profiles are 6061 and 6063, being renowned for their great resistance to corrosion and good machinability, as well as an excellent strength-to-weight ratio.

Dimensional Standards: Dimensional consistency is crucial for interoperability and assembly. Tolerances with respect to linear dimensions, angles, and geometric characteristics are detailed in ISO 2768. This will provide full assurance that the profile will properly match other components of the assembly.

Mechanical Property Standards: Standards such as ASTM B221 in the U.S. and EN 755 in Europe define the properties of the mechanical extruded aluminum profile. It includes tensile strength, yield strength, and elongation. Adhering to these ensures that profiles perform as expected under specific loads and conditions.

Surface Finish Standards: Surface treatments such as anodizing, powder coating, and polishing increase the durability and aesthetic appeal of aluminum profiles. Standards like ISO 7599 regulate the quality of anodized finishes, specifying criteria like thickness, color uniformity, and corrosion resistance.

Conclusion

Aluminum profiles are essential in industries ranging from aerospace and automotive to construction and consumer electronics. They can offer unparalleled versatility and performance when selected and applied correctly. By understanding the various types and adhering to recognized standards, manufacturers and designers can ensure that aluminum profiles meet both functional and regulatory requirements.