-

- Assign a menu in Theme Options > Menus WooCommerce not Found

- Newsletter

Why Extruded Aluminum Profiles Are Ideal for Lightweight Structures?

2024-11-18

Extruded aluminum profiles have become a cornerstone in modern engineering and construction, especially for applications requiring lightweight yet robust structures. Their unique combination of strength, flexibility, and adaptability make them the material of choice in industries ranging from aerospace to automotive.

In this article, we will explore the reasons why extruded aluminum profiles are ideal for lightweight structures, and what specific benefits they bring to various applications.

Lightweight Nature of Aluminum

The most notable feature of aluminum is its low density, so it is naturally light in weight. The density of aluminum is about one-third of steel, enabling it to achieve significant weight savings without compromising structural integrity. This is a significant advantage in industries like aerospace and automotive, where weight reduction directly improves fuel efficiency and performance.

Extruded aluminum profiles further take advantage of this natural factor by optimizing the use of the material in their design. The process of extrusion allows the creation of hollow or complex cross-sections that can minimize weight without sacrificing or even increasing structural strength.

Strength-to-Weight Ratio

One of the major reasons why aluminum profiles work so well in lightweight applications has to be their excellent strength-to-weight ratio. Although light, aluminum has very high tensile strength, especially when alloyed with other metals like magnesium, silicon, or zinc, which enhances its mechanical properties for demanding structural applications.

The extrusion process further strengthens the aluminum by aligning the grain structure along the length of the profile. This structural alignment enhances the load-carrying capacity and rigidity of the profile, making it ideal for load-bearing applications such as trusses, frames, and supports in architectural and industrial use.

Design Flexibility and Customization

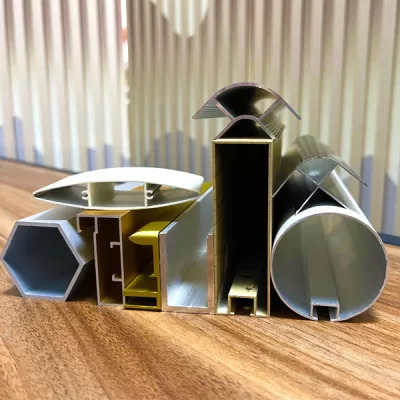

The extrusion process used in manufacturing provides the most unique design flexibility with aluminum profiles. By extruding, manufacturers are able to make a wide range of geometries and cross-sectional forms, from simple L-angles and T-bars to intricate, special profiles. This enables engineers and designers to achieve the highest strength with minimum weight by optimizing the geometry of a structure.

Besides this, due to the nature of aluminum profiles, which can be made into any shape required for a particular application, no material is wasted. For example, aerospace engineers design profiles that meet exact weight and performance requirements using thin walls and hollow sections.

Corrosion Resistance

Another feature of aluminum contributing to its advantages over competing materials in lightweight structural applications is its natural resistance to corrosion. When exposed to air, aluminum forms a thin oxide layer, which can prevent further severe oxidation and environmental degradation even under harsh conditions.

For lightweight structures exposed to the weather, such as bridges, railings, or frames for solar panels, this corrosion resistance equates to longer service life and lower maintenance costs. In industries like marine or offshore construction, where saltwater corrosion is a major concern, aluminum’s resilience is an invaluable asset.

Ease of Fabrication and Assembly

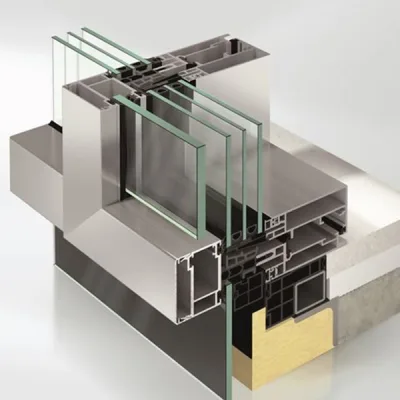

Extruded aluminum profiles are easy to fabricate and assemble, which simplifies the construction of lightweight structures. Aluminum can easily be cut, drilled, welded, or machined by standard tools. Many extruded profiles feature pre-designed slots, channels, and connections that make for quick assembly with a minimum of fasteners or welding.

This fabrication facility makes aluminum profiles very useful in modular designs. In the construction of lightweight buildings or temporary structures, aluminum profiles can be prefabricated and assembled on-site, significantly reducing construction time and labor costs.

Conclusion

Extruded aluminum profiles are ideal for lightweight structures because they combine the inherent properties of aluminum with the versatility and precision of the extrusion process. Their exceptional strength-to-weight ratio, design flexibility, and ease of fabrication make them indispensable in modern engineering and construction.